Optimal Timing for Concrete Finishings

Concrete finishings are a critical aspect of construction and renovation projects, influencing both aesthetics and durability. Proper timing ensures optimal results, preventing issues such as cracking, uneven surfaces, or surface deterioration. Understanding the ideal conditions for applying concrete finishings can significantly extend the lifespan of the surface and reduce maintenance costs.

Concrete finishings should be applied when ambient temperatures are between 50°F and 85°F to ensure proper curing and adhesion.

Rain, snow, or excessive heat can compromise the finish quality. It's best to schedule during dry, moderate weather conditions.

The surface must be sufficiently dry but not too dry to allow proper bonding of the finishing material.

Allow sufficient curing time before applying finishings, typically 7 days for most concrete types.

Proper surface prep is essential for a quality finish.

Techniques vary based on desired texture and appearance.

Proper curing enhances durability and finish quality.

Ways to make Concrete Finishings work in tight or awkward layouts.

Popular materials for Concrete Finishings and why they hold up over time.

Simple add-ons that improve Concrete Finishings without blowing the budget.

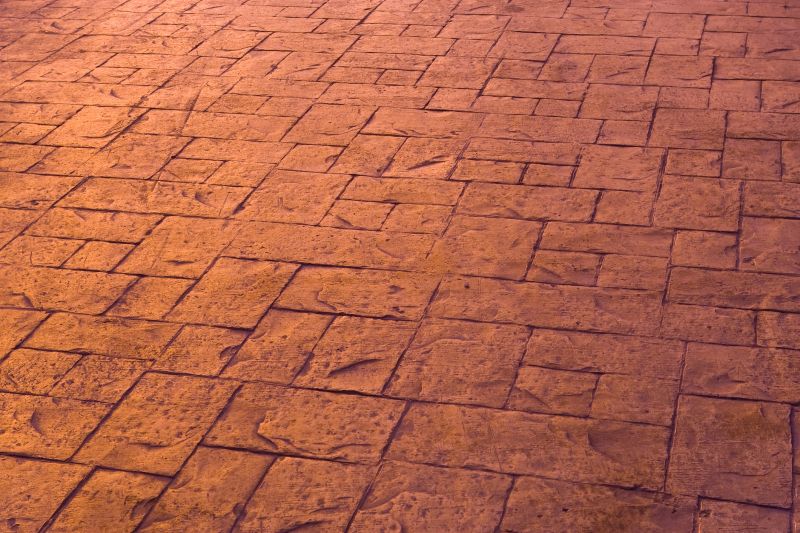

Concrete finishings encompass a variety of surface treatments, including polishing, stamping, staining, and sealing. These processes not only enhance visual appeal but also protect the concrete from wear and environmental damage. The choice of finish depends on the project requirements, location, and desired aesthetic. Proper timing and application techniques are crucial to achieving a durable and attractive surface.

Provides a smooth, glossy surface ideal for interiors.

Creates decorative textures resembling stone or brick.

Adds vibrant color and depth to surfaces.

Offers protection against stains and moisture.

High-end options that actually feel worth it for Concrete Finishings.

Finishes and colors that play nicely with Concrete Finishings.

Little measurements that prevent headaches on Concrete Finishings day.

A 60-second routine that keeps Concrete Finishings looking new.

| Timing Aspect | Recommended Conditions |

|---|---|

| Temperature | 50°F to 85°F for optimal curing and finishing |

| Weather | Dry, moderate conditions; avoid rain and extreme heat |

| Surface Moisture | Surface should be dry but not overly dry |

| Season | Spring and fall are most suitable |

| Curing Period | Minimum of 7 days before applying finishings |

| Humidity Levels | Moderate humidity to prevent rapid drying |

| Time of Day | Early morning or late afternoon to avoid midday heat |

Timing is a key factor in achieving high-quality concrete finishings. Proper planning around weather conditions, temperature, and surface readiness ensures the longevity and aesthetic appeal of the finished surface. Consulting with professionals can help determine the best window for application based on local climate and project specifics.